Air-conveying process can be easily lead to dust and streamers depending on flowing conditions. In dilute phase and high speed conveying, it can create large amount of dust and streamers, while at low speed, it may generate thin dust from collision.

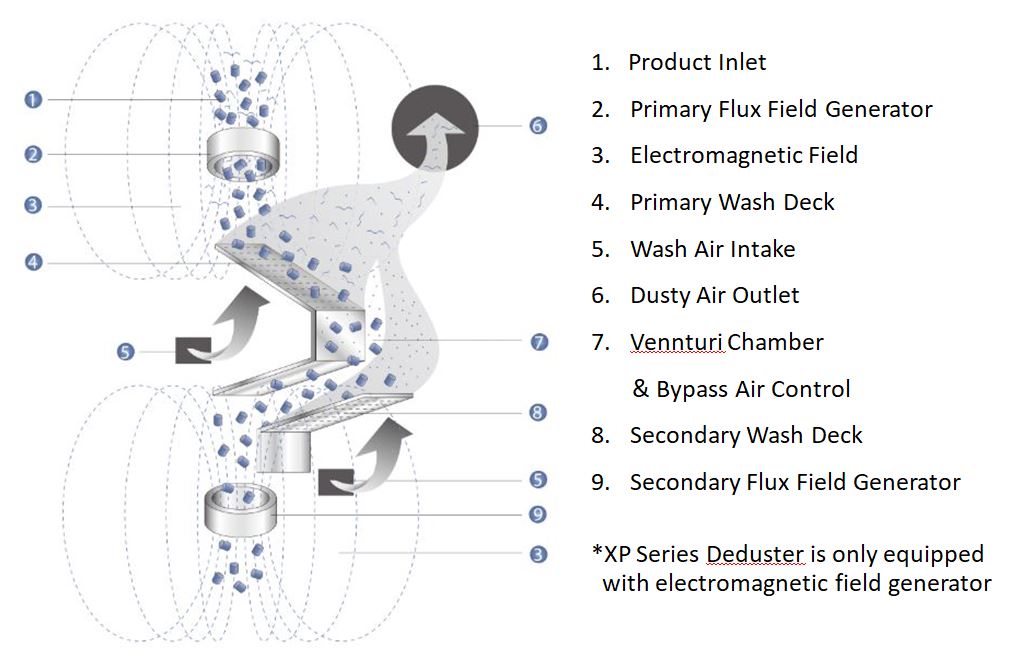

Pellerton Deduster series is designed and patented specifically for industrial dedusting purposes. By using the electromagnetic field to remove static electricity on the particles and the patented special feature for air-cleaning filter, it effectively separates dust and particles.

Pellerton Deduster serves for a wide range of usage in multiple industries, including plastic processing and plastic manufacturing industries, as well as for food, mineral, pharmaceutical, chemical and other applications.

Operating Process

XP Series Deduster

*Extra low height & extra in low energy consumption.

*XP15 to XP900 are equipped with double wash decks.

Wash Down DeDuster

*This design is based on a standard XP-design for wash down applications.

*The design allows for cleaning with water and easy access to all areas of the deduster.

Wide Body Design

*For some retrofit applications, the available height is not sufficient for the installation of a standard deduster.

*Pelletron offers a wide body version of the P and XP series in order to reduce the construction height.

Note : Selection of the deduster model depends on the bulk density of the product being cleaned, the shape of the pellets and the type and quantity of the fines.

deduster_xp_series_table

RC Series Deduster

*This low height deduster is designed for a wide range of products with capacity ranges from 10lbs/hr (5kg/hr) up to 700lbs /hr (350kg/hr).

*The round design allows for a reduction in height and lower energy consumption.

*Larger sizes are available upon request.

OS Series Deduster

*This Deduster has an offset inlet outlet design. It can be used for applications with inclined piping or other configurations that require an offset design

*Various sizes are available and others can be designed based on unique customer

requirements.

DO Series Deduster

*This Deduster has a single inlet and a dual outlet. It can be used for special applications where narrow or shallow packaging machines are installed or other

configuration that required a dual design.

*Various sizes are available and others can be designed based on unique customer

requirements.

Pellbow

Pellbow – Significantly reduce dust & streamers

The Pellbow resists wear naturally.

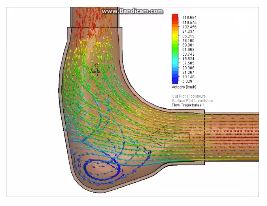

In traditional long radius elbow installations, the conveyed product slides along the

elbow wall at a high velocity. The strong centrifugal force presses the product

against the outer metal surface. This causes friction and heat, which create streamers

and breakage. In contrast, material flowing through the Pellbow accumulates in the

pocket or “impact zone” and moves slowly upward and out. Incoming material

is deflected at 90 degrees with minimum resistance and no impact damage.

Applications

All high and low-density dilute phase systems.

*Plastic pellets, other granules and abrasive products.

*Replacement of long-radius and short-radius elbows and other pipe bends.

Options

*All sizes are available in AL,SST and CS.

*Abrasion resistant alloy versions and coatings are available upon request.

*Flanges are available in ANSI,DIN and JIS。

*Stub end version for compression coupling connection is available for tube and

pipe.

*Loose flanges available in AL, SST and CS.

*Special designes and fittings are available upon request.

Reviews

There are no reviews yet.